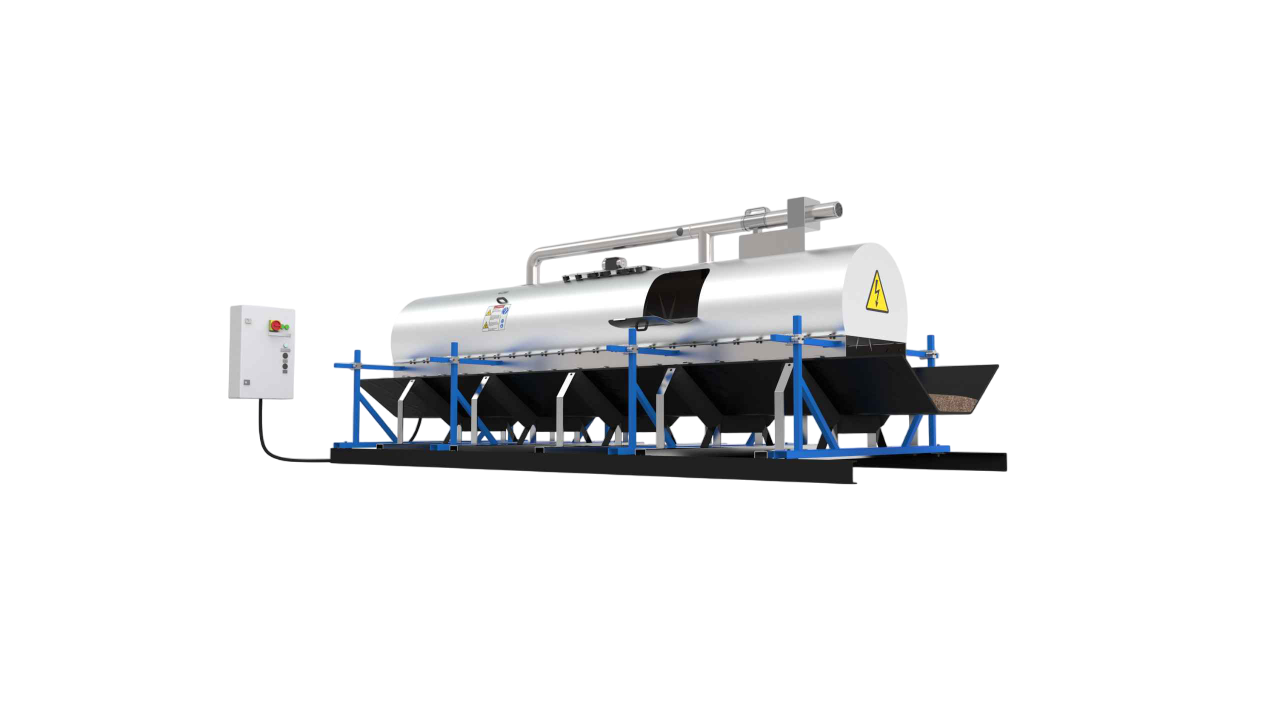

The high voltage creates free electrons that ionize the air. The ionization charges the dust particles and they are collected on the collector. This collector is the inner part of the housing where the dust particles are shaken by a vibration motor that runs periodically.

Our systems are suitable for different situations in bulk material handling. Especially at conveyor material transfer points, at the chute outlet, at crusher or feeder and screen outlets and on top of silos.

Very low operating costs

Very low power consumption

Very low maintenance costs (no additional downtime required)

No water required

No change in material properties

No material loss

Our systems guarantee very high dust suppression with extremely low operating and maintenance costs

.

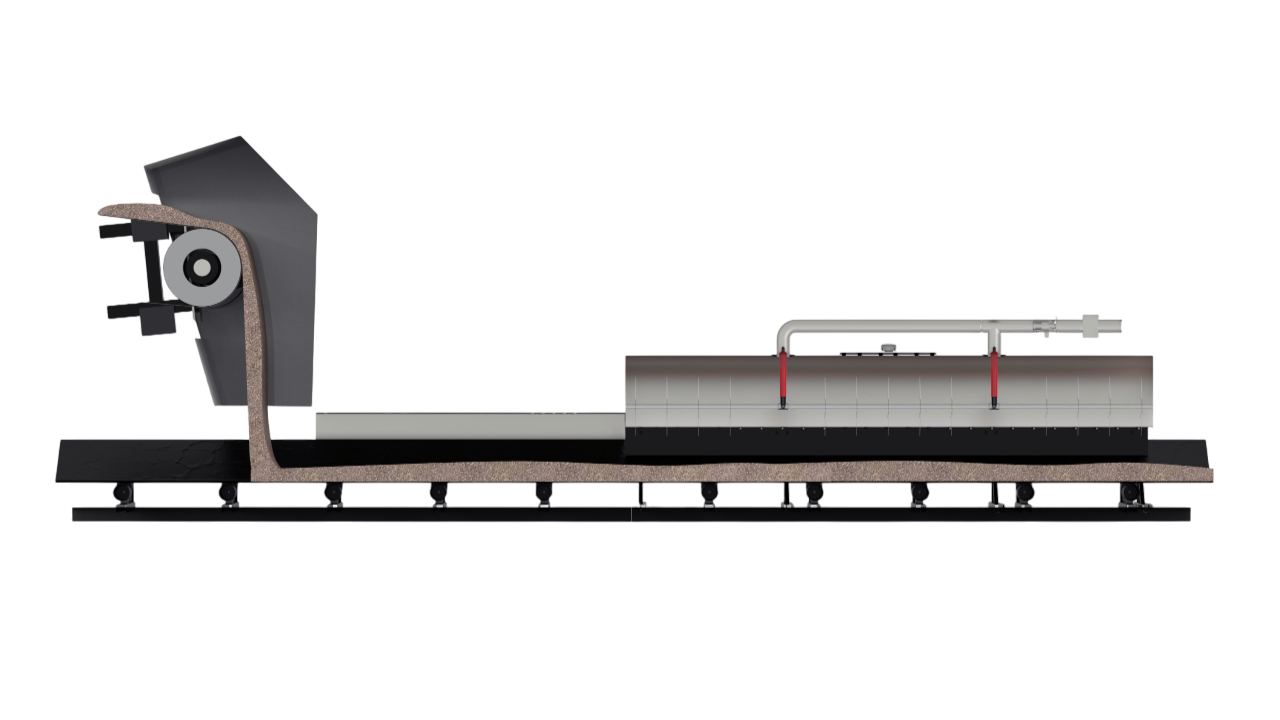

Our systems are available in different versions for the respective requirements. The length of a device can vary in 1 m intervals, the smallest system is 2 m long and the largest is 7 m long. Multiple systems can also be placed back to back. The width of a device depends on the conveyor belt and starts from a conveyor belt width of 500 mm. If the width exceeds 1400 mm, several devices can be placed side by side.