They can be used in all types of applications. They can be used on tapes spliced with mechanical attachment (fastener).

They are made of polyurethane and have very good abrasion resistance. It consists of 150 mm wide segments. They can move independently of each other. As an advantage of polyurethane, they adapt very well to the tape and can be used on tapes attached with thumbtacks. The blades can be changed very easily and conveniently, and thanks to the way they are mounted on the axle, you can install them without using any hand tools.

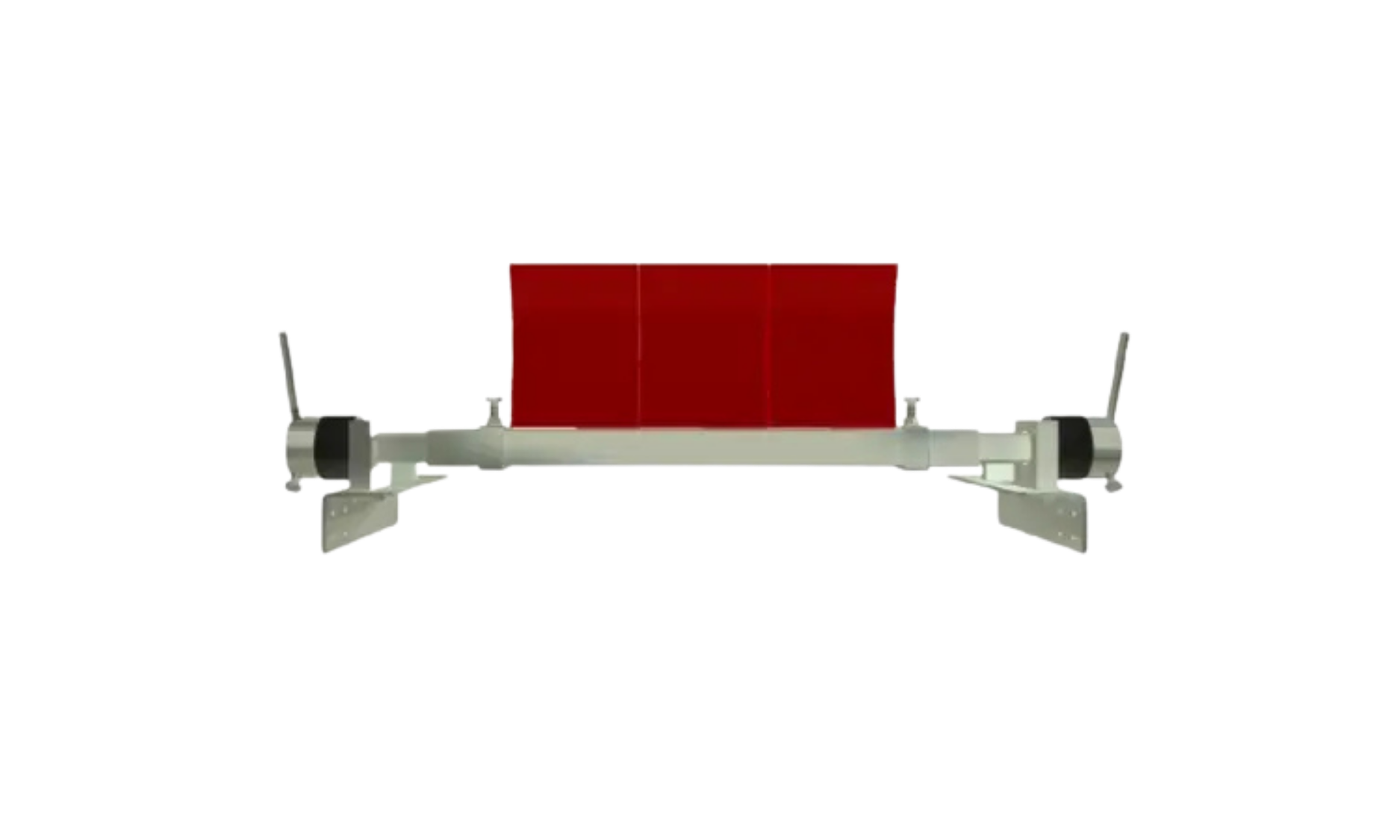

Saport has an “Automatic Pressing System”, which is protected from external influences by a rubber casing that gives continuous pressure to the belt by means of a spring. This system ensures that the blades are constantly tangent to the belt, ensuring efficient cleaning and protecting the blades from impacts. The Automatic Press System is connected to the scraper’s fixing arm. This fixing arm is a very robust U-profile structure. Saports have a slide system to determine the position of the scraper.

Saportes have an expansion of 200 mm on both sides. This allows them to adapt to different widths of belt chassis.