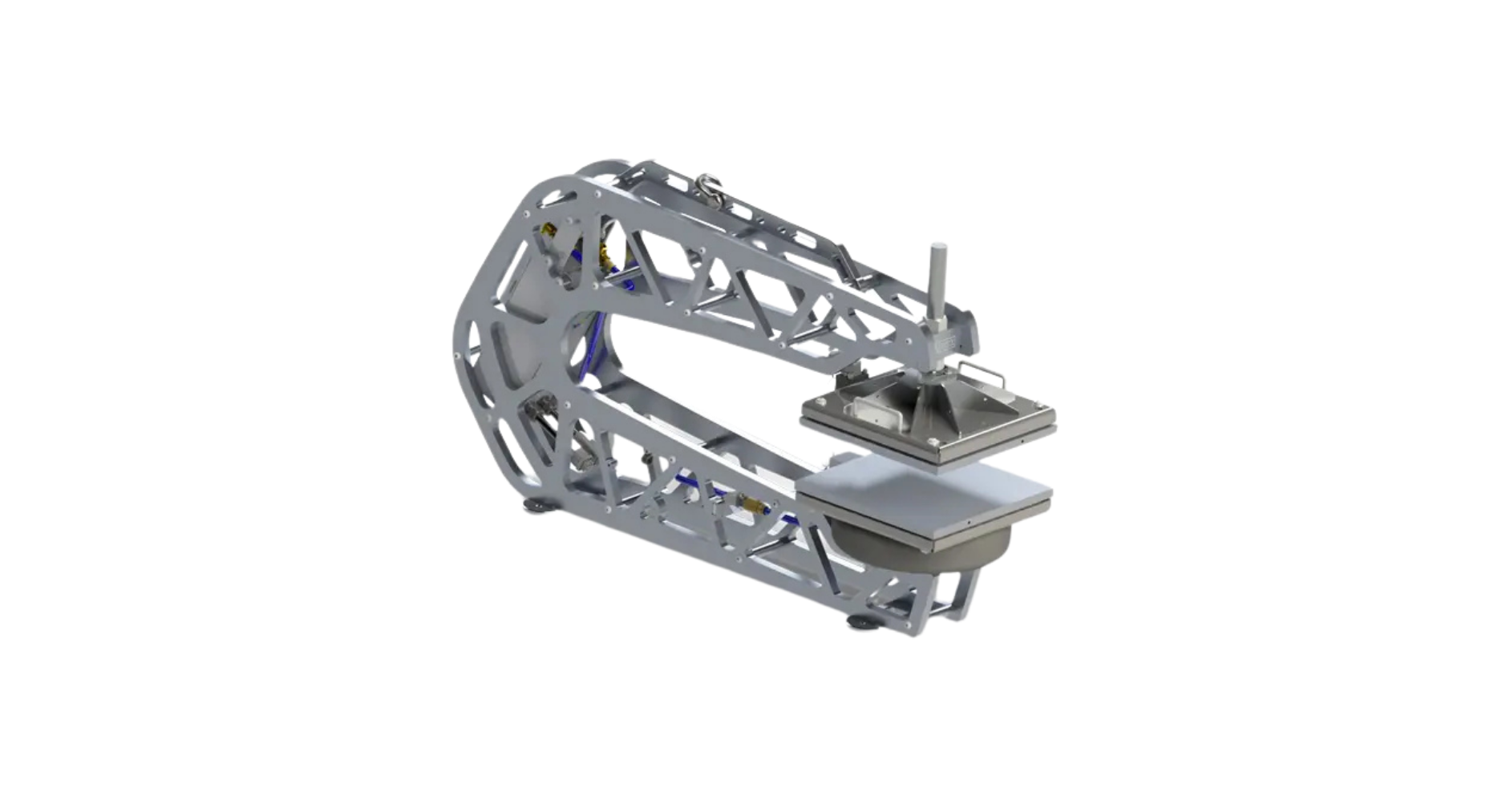

Superspotter max (SSP MAX) is the latest almex spot and tear repair press for heavy rubber band maintenance

SuperSpotter Max (SSP MAX) is the latest Almex spot and tear repair press for heavy rubber band maintenance. Use these presses in the field or in the workshop to repair small tears and holes. The SSP MAX comes with 305 mm x 305 mm (12“ x 12”) plates, 7 kg/cm² (100 PSI) and 2 sizes suitable for 1500 mm (60“) and 2000 mm (78”) belt width.

Why is Almex Different?

- Easy to use

- Built-in frame controls

- Optional air compressor (inside the frame)

- Corrosion-resistant aircraft-grade aluminum frame

- -Lightweight, Strong and Portable Aluminum Frame

- -Lighter frame than traditional SSP4 Model (~5%)

- -Convenient handles on the frame and top roller

- -3 lifting hooks on top handle for positioning in the field

- -Maximum Bandwidth: 1.5M: 1500 mm | 60” or 2M: 2000 mm | 78”

- -Reliable Pressure and Heating controls

- -Dual voltage; 110V – 220V

- -Quick connect air connector

- -Unique air spring actuator pressure system for fast and even pressure inflation

- -P.I.D. temperature controller produces accurate temperature profile

- -Includes pressure safety relief valve

In-frame controls for temperature, pressure and cooling

Expanded graphite heating element provides very fast warm-up time, 10 minutes at 110V and 10 minutes at 220V - -CE Certified

- -Quality Almex 305 mm x 305 mm (12“ x 12”) rollers

- -Special “Extruded Plank” rapid cooling system inside the rollers

- -Rollers can rotate up to 45 degrees

- -65 mm (2 ½”) Daylight Opening

- -Removable plates with carrying case for ease of transportation

- -1500 mm or 2000 mm maximum bandwidth

- -Can be used with remote control (T2, T6)

- -Soil Fault unit available on request

- -Ability to use a longer roller for tearing operations by connecting multiple SSP MAX frames, available on request as a special order

- -Custom graphic panels available upon request