The most abrasion resistant material on earth for the toughest jobs around the globe.

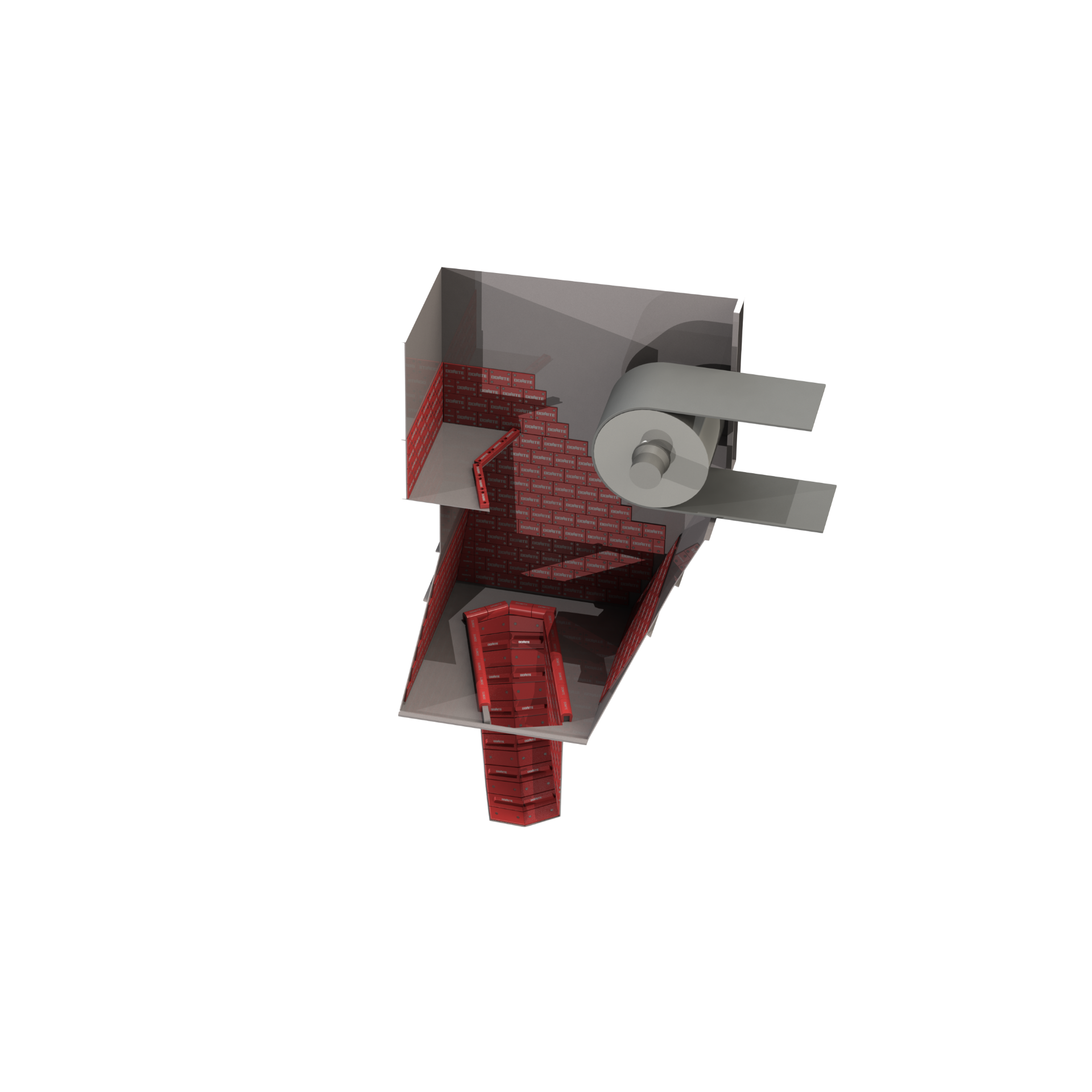

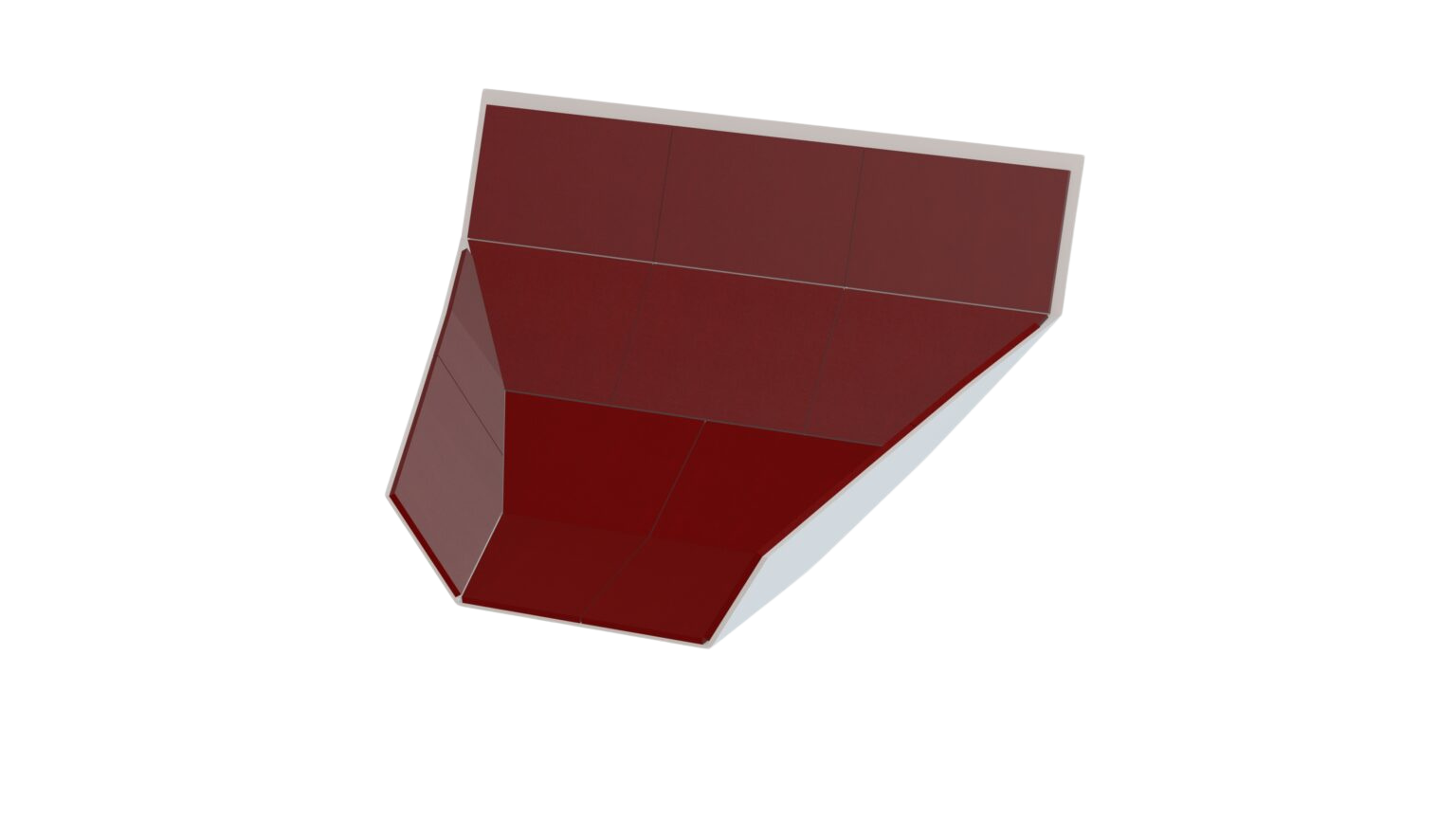

In continuous operations, equipment and facilities are regularly subjected to excessive wear. Planned and unplanned downtime greatly increases maintenance costs and lost production. In particular, areas where physical access is difficult pose an enormous health and safety risk. This, coupled with the constant drive to reduce the cost of production per ton, requires the use of a material with superior abrasion resistance.

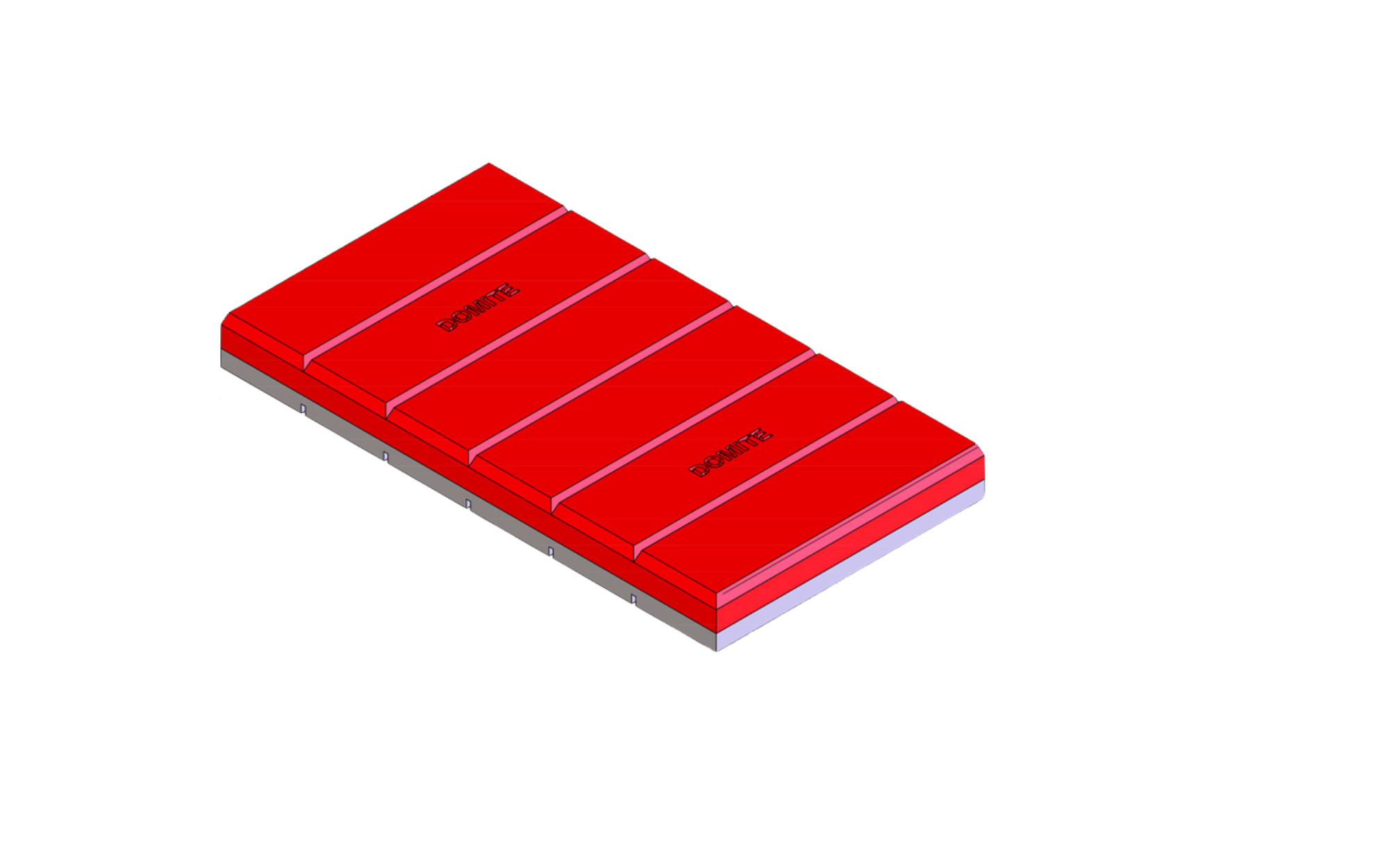

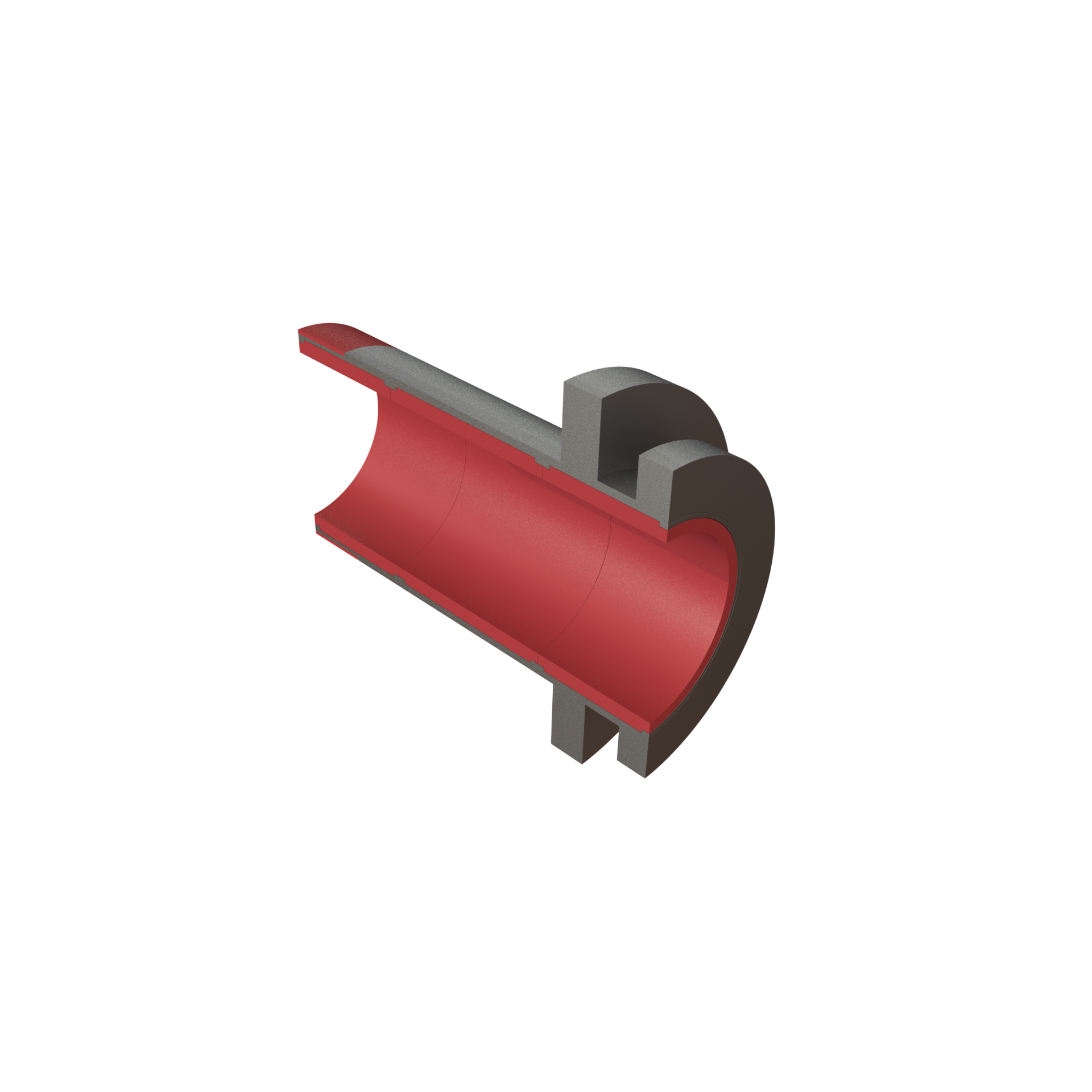

Domite® is the most wear resistant material available, combining an extremely hard chrome-white iron wear surface (700 BHN – 63 Rc) with the machinability of mild steel as a backing plate through metallurgical diffusion bonding. This creates a highly impact and abrasion resistant product that retains ductile properties for easy connection.

- The National Research Council (“NRC”) conducted a resistance test on wear materials.

- It did not set out to do so, but emphasized Domite’s superior qualities in terms of hardness (BHN) and longevity/resistance compared to other materials on the market.

- Domite® 755 is the hardest material tested with BHN and matches the best wear ratio of 1.

- For example, it is 350 BHN harder than Domite® AR450 and lasts 9.5 times longer.

The most wear-resistant material in the world for the toughest jobs around the globe.