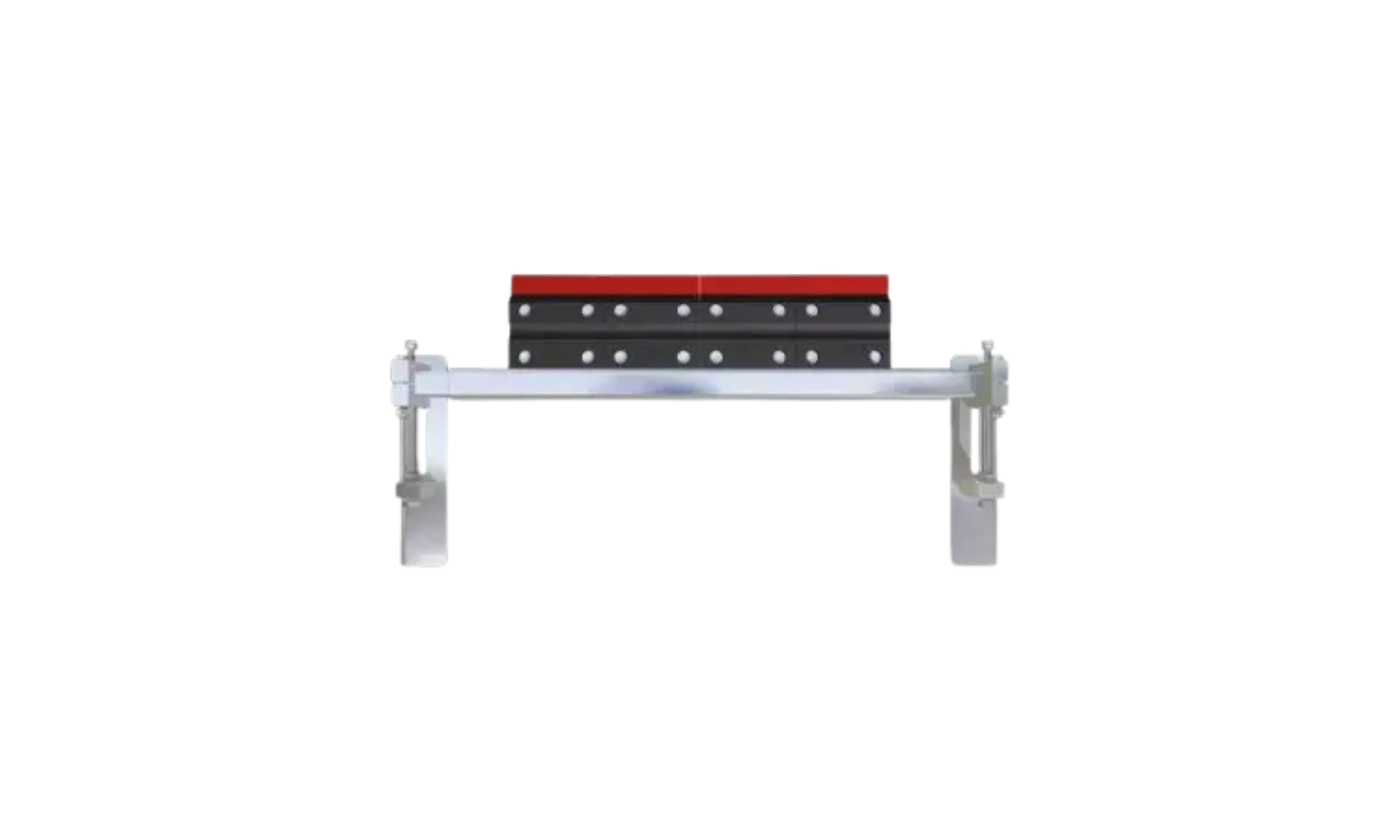

DST Bidirectional Secondary Scraper

Scraper Blades

They work perpendicular to the belt axis. The blades are made of tungsten and their abrasion resistance is very high. Scraper blades are fixed to rubber saports by means of 2 bolts. In this way, their replacement is very fast and easy.

Saports are specially designed for bidirectional tapes. Each saport has an individual pressure system inside. In this way, it applies as much pressure on the belt as required where required. Each segment consists of 124 mm wide rubber parts and is easily mounted on the main axle of the scraper.

The saport contains an adjustable pressure system. The pressure system is connected to the fixing arm of the scraper. This fixing arm is a very robust structure made of L-profile. Saports have a slide system to determine the position of the scraper. Saports have an expansion of 200 mm on both sides. In this way, they can be adapted to different widths of belt chassis.