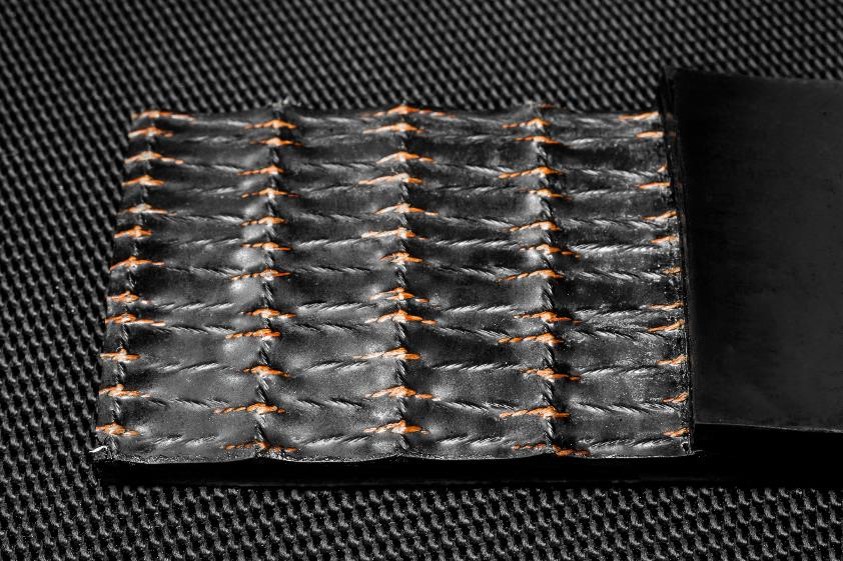

Dunlop Ferroflex has a tension layer of longitudinal steel cords through which the power transmission takes place. Transverse steel cords reinforce the tape and protect it against impacts and tears. This proven carcass structure has particularly good ‘low elongation’ properties.

Ferroflex: Durable and Adaptable Solutions for Harsh Service Conditions

Ferroflex is the perfect, highly durable solution wherever tensile strength and coating grade qualities need to be adaptable to meet demanding service conditions. This applies to all areas of bulk material handling, especially long-haul applications and high impact conditions.

There are two Ferroflex constructions, referred to as ‘FIW’ and ‘FSW’. The FIW carcass has a single transverse steel cord layer above the longitudinal steel courts, while the FSW has two transverse steel cord layers on either side of the longitudinal steel courts.

Ferroflex provides world-class reliability and durability across a wide cross-section of industries including cement, quarries, wood, paper, pulp, recycling, steel and conveying. FSW reinforced belt can be supplied with cable-free zones to facilitate the installation of buckets and fasteners and to create a dynamically stronger belt, ideal as elevator belt where it is used in conjunction with high temperature resistant Deltahete rubber coatings for handling hot materials.

Ferroflex FIW and FSW tapes are custom made to order and can be supplied in all Dunlop coating grades. All Ferroflex tapes are supplied with molded rubber edges. Available in widths from 500mm to 2000mm. Tensile strengths (N/mm): 500, 630, 800, 800, 1000, 1250, 1600 and 2000

This conveyor is of great importance in the field as any stop causes loss of production.