Slider belts are most commonly used for the transportation of individual products and packages.

Dunlop slider bands have a special rubber layer that provides the necessary transverse stiffness to create the flat, even surface needed to run smoothly and efficiently. The low-friction polyester fabric used on the underside of the belt provides low power consumption properties. Rufftop and Fishbone profiled overlays are often used on slider belts to provide the surface grip needed to prevent slipping when it comes to steep slopes.

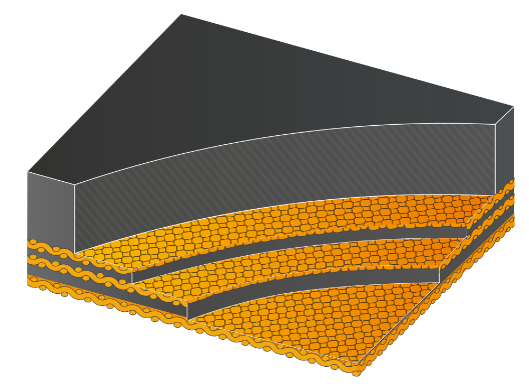

The carcass consists of 2 or 3 layers plus a low friction (low power consumption) polyester fabric slider layer.

The slider belt is used in plants where the upper idlers are replaced by wooden, metal or plastic slider plates. These installations are ideal for the transportation of individual products or raw materials.

Dunlop slide bands are available from stock in 250/2 with a high abrasion resistant coating grade and 400/3 with both ROM (vegetable) and ROS (mineral) oil resistant coatings. A 250/2 version with rufftop profile is also available. Other features, including fishbone profile top coating, can be made to order. Available in widths up to 2000mm.

A 250/2 version with rufftop profile is also available. Other features, including fishbone profile top coating, can be made to order. Available in widths up to 2000mm.