They are used in all kinds of applications and especially on conveyors transporting highly abrasive materials.

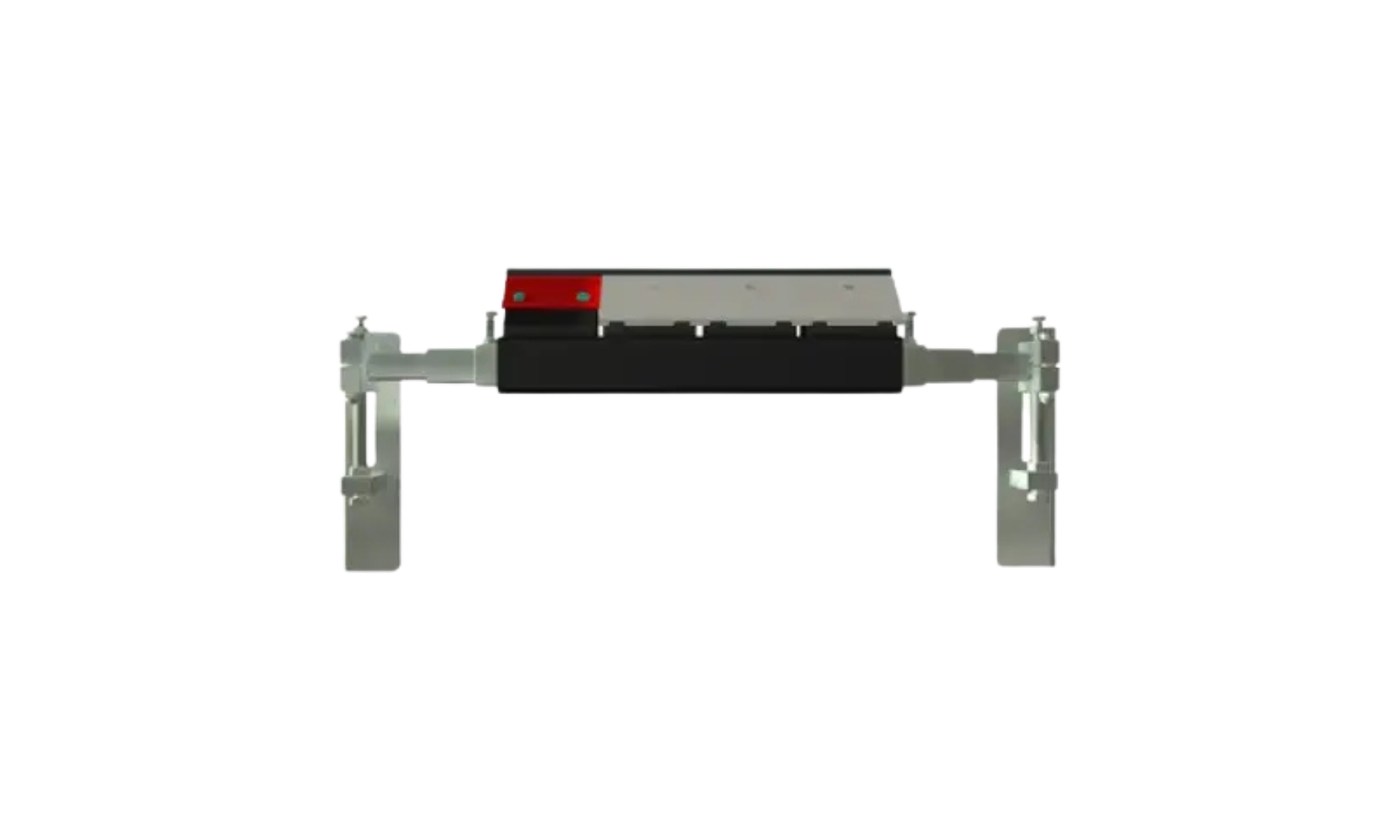

Scraper Blades

They are placed perpendicular to the direction of movement of the belt, thanks to the special design they prevent the accumulation of the stripped material. The blades are tungsten based and have a very high abrasion resistance and are mounted with 2 bolts to the rubberized saports. This makes them very easy to install.

Saports are designed to provide flexibility to the blades. The rubber saports are extremely effective in absorbing vibrations and incoming impacts. Saports are in rubber segments and each segment is 124 mm wide. They are easily mounted on the main axle. They are manufactured with a combination of two different hardnesses of rubber. The hard rubber segment (the part that wraps around the axle) provides a firm grip on the axle, while the softer segment (the curved part) gives the blades flexibility in all directions.

The saport contains an adjustable pressure system. The pressure system is connected to the fixing arm of the scraper. This fixing arm is a very robust structure made of L-profile. Saports have a slide system to determine the position of the scraper. Saportes have an expansion of 200 mm on both sides. This allows them to adapt to different widths of belt chassis.